Fire safety is a paramount consideration in construction and design.

As the demand for sustainable building materials increases, the fire resistance of these materials becomes a crucial aspect to ensure the safety and security of occupants.

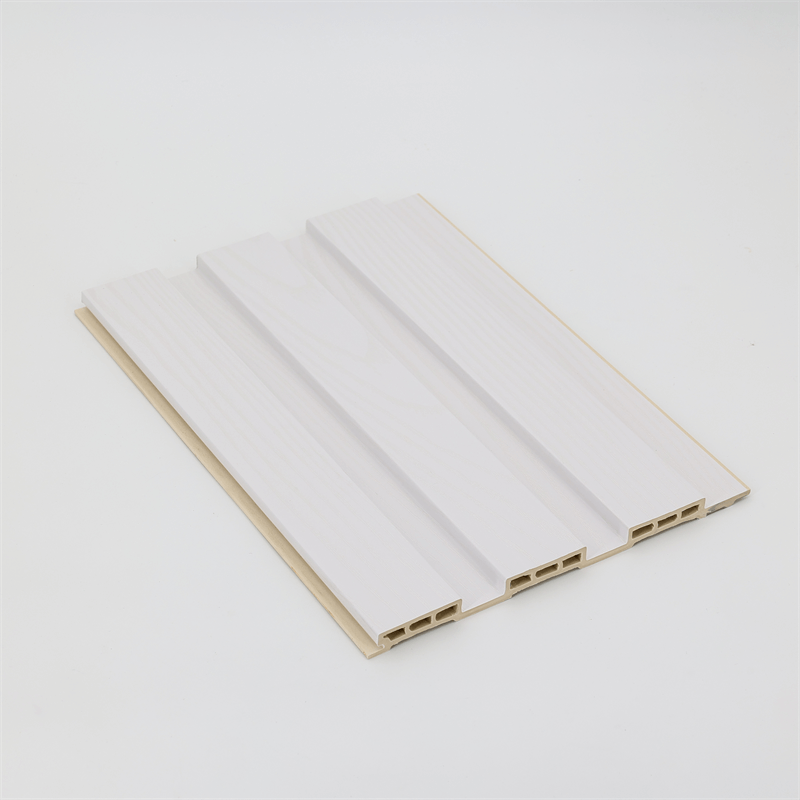

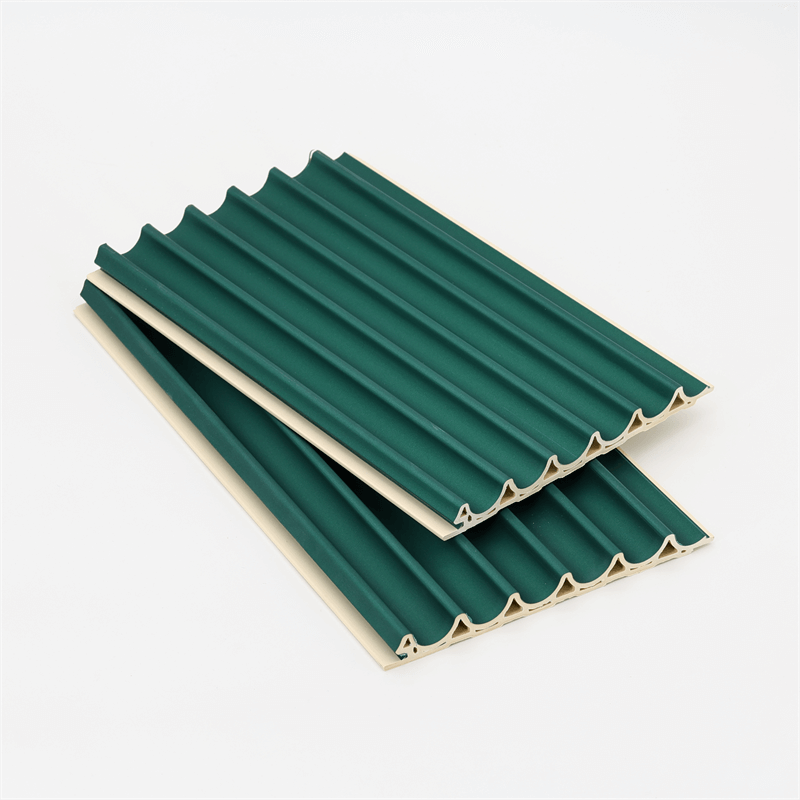

Wood-Plastic Composite (WPC) wall panels have gained popularity in recent years due to their sustainability and versatility.

This essay delves into the fire resistance of WPC wall panels, exploring their performance, fire safety standards, fire retardant treatments, and applications in fire-prone areas.

I. Performance of WPC Wall Panels in Fire Conditions

Understanding the behavior of WPC wall panels in fire conditions is essential to assess their fire resistance.

WPC panels exhibit different performance characteristics compared to traditional wood or plastic materials.

WPC panels contain a blend of wood fibers and plastic polymers. The presence of wood fibers can contribute to the combustibility of the material.

However, the addition of plastic polymers can enhance the fire resistance properties of WPC panels, creating a balance between structural integrity and fire safety.

When exposed to fire, WPC panels show a slow rate of flame spread and reduced smoke emission compared to solid wood.

This characteristic is attributed to the limited availability of fuel in the plastic matrix, which hinders the propagation of fire.

It is important to note that the fire resistance of WPC panels can vary based on factors such as the formulation of the material, panel thickness, and installation techniques.

Proper design, installation, and maintenance are critical to ensure optimal fire performance.

II. Fire Safety Standards for WPC Wall Panels

To assess and ensure the fire safety of construction materials, including WPC wall panels, various fire safety standards and regulations are in place.

These standards define the required fire performance characteristics and establish testing methods.

In many regions, fire safety standards such as the National Fire Protection Association (NFPA) codes

European Standard (EN) classifications, and ASTM International standards provide guidelines for evaluating the fire performance of building materials.

Tests such as the ASTM E84 (Standard Test Method for Surface Burning Characteristics of Building Materials) and EN 13501-1 (Fire classification of construction products and building elements) evaluate the flame spread, smoke development, and heat release properties of materials, including WPC panels.

Adhering to these fire safety standards helps ensure that WPC wall panels meet the necessary requirements for fire resistance, providing a level of safety and compliance in building construction.

III. Fire Retardant Treatments for WPC Wall Panels

To enhance the fire resistance of WPC wall panels, various fire retardant treatments can be applied.

These treatments aim to reduce the combustibility and slow down the spread of flames in case of a fire event.

One common method involves the incorporation of fire retardant additives during the manufacturing process of WPC panels.

These additives can improve the material’s ability to resist ignition and limit the spread of flames.

Additionally, surface treatments and coatings can be applied to WPC panels to further enhance their fire resistance.

These treatments create a barrier that delays the ignition and provides additional protection against fire hazards.

It is important to note that fire retardant treatments should be carefully selected and applied according to the specific requirements and fire safety standards of the project.

Regular maintenance and inspection of treated WPC panels are necessary to ensure their continued fire resistance performance.

IV. Applications of WPC Wall Panels in Fire-Prone Areas

WPC wall panels find applications in a wide range of environments, including areas prone to fire hazards.

Their fire resistance properties make them suitable for such applications, providing an added layer of safety and protection.

In exterior settings, such as building facades and cladding, WPC panels offer an alternative to traditional combustible materials.

Their fire-resistant characteristics contribute to reducing the potential for fire spread, enhancing the overall safety of the structure.

WPC panels can also be used in interior spaces, including public buildings, commercial areas, and residential properties.

Their fire resistance properties provide peace of mind to occupants, ensuring a safer environment in case of fire emergencies.

The fire resistance of WPC wall panels is a crucial aspect to consider in construction and design.

While WPC panels contain wood fibers, the addition of plastic polymers enhances their fire resistance properties.

Understanding the performance of WPC panels in fire conditions, adhering to fire safety standards, and applying appropriate fire retardant treatments contribute to their fire resistance capabilities.

WPC wall panels can be utilized in various applications, including fire-prone areas, to enhance the overall fire safety of buildings.

However, it is important to note that proper design, installation, and maintenance are essential to ensure optimal fire performance.

By exploring the fire resistance of WPC wall panels and implementing appropriate measures, architects, builders,

and designers can create spaces that prioritize both sustainability and fire safety, ensuring the well-being and security of occupants.

In conclusion, the fire resistance of WPC wall panels is a crucial consideration in construction and design.

These panels offer a sustainable alternative to traditional wood materials while providing enhanced fire safety.

With their unique composition of wood fibers and plastic polymers, WPC panels exhibit improved fire performance, including slower flame spread and reduced smoke emission.

Adhering to fire safety standards and regulations ensures that WPC wall panels meet the necessary requirements for fire resistance.

Testing methods, such as ASTM and EN standards, evaluate the flame spread, smoke development, and heat release properties of the panels.

Implementing fire retardant treatments during manufacturing or applying surface coatings further enhances their fire resistance capabilities.

The applications of WPC wall panels extend to fire-prone areas, providing a safer alternative to combustible materials.

Whether used in exterior facades or interior spaces, these panels contribute to the overall fire safety of buildings, offering peace of mind to occupants.

However, it is important to emphasize that proper design, installation, and maintenance are crucial to ensure the optimal fire performance of WPC wall panels.

Careful consideration of fire safety measures, adherence to standards, and regular inspections help maintain their fire resistance properties over time.

Incorporating fire-resistant WPC wall panels in construction and design projects not only promotes sustainability but also prioritizes the safety and well-being of occupants.

By exploring the fire resistance of WPC panels and implementing appropriate measures, architects, builders, and designers can create spaces that strike a balance between aesthetics, functionality, and fire safety.